ISKU’s responsibility acts from 2011 to 2022

ISKU has systematically and successfully developed its corporate responsibility for the past eleven years (2011-2022). Today, responsibility is an integral part of all ISKU operations, and we will maintain a strong advocacy and pioneer of responsibility in the future as well. The operations are based on meeting the expectations of customers and stakeholders and exceeding the requirements of environmental regulations and legislation. For ISKU, responsibility is action. We are determined to become a carbon-neutral manufacturer in 2023, and this is an important project that will take us a big leap closer to our goal. We want to stay a pioneer and a trendsetter when it comes to sustainability.

ISKU has certified management systems that ensure responsible operations with continuous improvement.

Certified ISO 9001 Quality Management System supports the continuous development of operations and processes. The system helps to meet customer expectations by standardizing operating methods and setting quality objectives.

Certified ISO 14001 Environmental Management System helps to improve processes and practices. In order to obtain an environmental certificate, the company must identify the environmental impacts of the organization and set targets to reduce them.

Certified OHSAS 18001 Occupational Health and Safety Management System combines occupational health and safety issues into everyday activities and management.

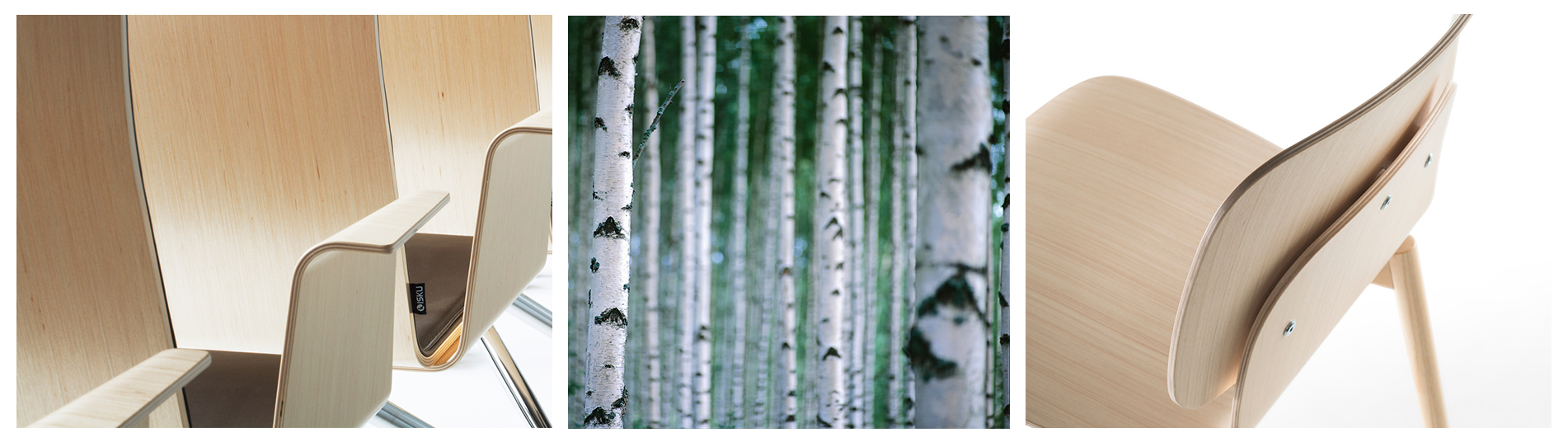

PEFC (Chain of Custody) – certified tracking system for wood origin ensures that the wood used in the company’s products comes from forests that are managed in accordance with the principles of sustainable development. In 2019 more than 93% of wood material used in ISKU products is PEFC certified, and the rest of wood material is FSC certified or audited by ISKU.

ISKU has centralized its entire production to Lahti, Finland.

ISKU has centralized its material and component procurement to Finland to reduce transport distances and thus emissions from unnecessary traffic.

Over 80% of purchases come from Finland, 15% from other EU countries and less than 5% from outside the EU.

The domestic content of ISKU’s lobby furniture, sofas and cabinets is up to 95%. ISKU is allowed to use the Key Flag Symbol to demonstrate that it’s products has been manufactured in Finland, creating Finnish jobs.

Responsible property management with energy-wise solutions have reduced the building’s CO¬¬2 emissions by up to 90%.

The energy management of ISKU’s HQ, ISKU Center, is based on an exceptionally efficient geothermal heat pump system that takes care of both the property’s heating and cooling. In all, ISKU Center has 50 geothermal wells, each 320 meters deep.

Solar panels are installed on the ISKU Center’s roof to harness the potential of its wide surface area, with the solar energy connected to various real estate needs such as powering air conditioning systems and electric vehicles.

Energy-saving measures are an integral part of the over EUR 100 million investment program.

In addition to the factory, the energy efficiency at the ISKU factory property has been improved through a major renovation of the building’s automation system, modernization of the ventilation units, renewal of the dust removal system, as well as new lighting where over 3,000 light bulbs were replaced with LED bulbs.

As a result of these investments, carbon dioxide emissions at the ISKU factory property have decreased dramatically, and the carbon footprint in 2019 was only 29.5 metric tons of CO2e.

Solvent emissions (VOC) to the air are negligible.

In recent years, ISKU has transitioned to using water-based varnishes, stains, and paints in production. Today, all upholstery adhesives are solvent-free.

ISKU does not require a separate environmental license to operate.

As a result of the responsible practices, the environmental impact of ISKU’s production is so minimal that operations have not required an environmental permit since 2015.

Environmental friendliness of materials:

The ISKU+ furniture collection is the world’s first antimicrobial furniture collection designed to contribute to a cleaner environment. Antimicrobial materials reduce infection routes with their unique features, incorporating innovations based on copper, silver, and other antimicrobial technologies on essential contact surfaces.

ISKU utilizes surplus material from the production of one product as the raw material for another. For example, the award-winning ISKU Kivikko seats and Amphi seating system were created through this process. In our innovative space-in-space solution, ISKU Nook, green lifecycle meets pedagogical sustainability. Both ISKU Kivikko and Nook have received recognition as the Best Sustainable/Eco-friendly products at the highly esteemed GESS Education Awards.

ISKU Kivikko seats and the Nook space-in-space solution have received recognition as the Best Sustainable/Eco-friendly products in the GESS Education Awards.

For suppliers, ISKU has established strict environmental requirements. The company’s goal is to enhance the environmental friendliness of all raw materials used in its products, reduce indoor air emissions, and ensure product recyclability at the end of the product’s life cycle.

Where possible, ISKU incorporates M1-certified materials in its products. M1 certification indicates a low level of indoor air emissions for materials (e.g., formaldehyde, VOC, ammonia, odors). ISKU’s office chair series, Still and Step+, are M1-certified.

The company exclusively uses CertiPUR-certified foam plastic, ensuring that materials have been tested and do not exceed limit values for chemicals that are hazardous to health or the environment.

ISKU has been granted the right to use the Nordic Swan Ecolabel on its main products. The criteria for this label are extremely strict, and only a small proportion of the furniture available on the market can meet them.

In its standard collection of public furniture, ISKU ensures that over 80% of the fabrics have been granted the EU eco-label or OEKO-TEX® label.

Furthermore, more than 99% of the waste generated in the manufacturing process is recycled as materials and energy.

ISKU is committed to using only recyclable packaging materials, which can be easily sorted without any special tools. In recent years, the company has developed chair packaging, for example, to reduce the amount of plastic used in wrapping, and it does not use chlorine-containing plastics.

The ISKU collection includes the world’s first M1 classified office chairs.

Responsibility in the Supply Chain

ISKU adheres to strict supplier selection criteria with quality and environmental requirements aligned with the company’s responsibility program.

Suppliers are bound by the ISKU Code of Conduct, which encompasses procurement and quality principles. In our code of conduct, we pledge to comply with all laws and regulations associated with our activities in every country where we operate. Regular audits are conducted to ensure our suppliers adhere to our code of conduct. Social responsibility audits are also regularly conducted for component suppliers located in high-risk countries.

Procurement has been systematically centralized to Finland. To enhance quality control, ISKU has reduced the number of suppliers from 700 to 100 companies.

Improving occupational health significantly reduces sick leave and absenteeism.

ISKU has a certified occupational health and safety system based on the ISO 45001 standard. The company’s safety management revolves around the continuous development and improvement of occupational health and safety, supporting employees’ performance. There is a dedicated occupational health and safety function that coordinates the management of all safety aspects. The occupational safety organization conducts workplace visits and audits covering operations throughout Finland.

In the factory, numerous investments have been made to enhance occupational health and safety. For instance, 100 forklifts have been reduced, and a focus on ergonomics has led to investments in new cranes and conveyors. As a result of systematic efforts to improve working conditions, the illness absence rate in 2019 was only 3%.